New Route to Synthesize High-Entropy Carbide Powders by Mechanical Alloying

Title: New Route to Synthesize High-Entropy Carbide Powders by Mechanical Alloying

Authors: R. Idczak, P. Sobota, L. M. Tran, M. Babij, K. Idczak, W. Nowak, A. Pikul

Journal: Metallurgical and Materials Transactions A

DOI: 10.1007/s11661-023-07263-x

High entropy carbides are solid solutions of carbon and four or more metal elements. The atomic concentration of each element is between 5 and 35 percent. These carbides are crystallographically ordered but chemically disordered. This means that equivalent positions in the crystal lattice are randomly occupied by different alloying elements. Physicists and materials scientists have recently taken a keen interest in them due to their exceptional properties. These properties include high melting points, hardness, strength, wear resistance, and anti-corrosion properties. As a result, they can be used as structural or protective materials in extreme conditions, making them ideal for the aerospace, mining, and military industries.

High entropy carbides with Ti, Zr, Hf, Nb, Ta, Mo, or W can be produced using spark plasma sintering (SPS) and hot sintering methods. However, these methods are expensive because they require transition metal carbides as starting materials and very high temperatures (above 1600oC) or high gas pressures (above 10 MPa). Despite the development of alternative synthesis methods, such as mechanical fusion (grinding) of pure graphite and metal elements or synthesis from molten salts, high temperatures are still required.

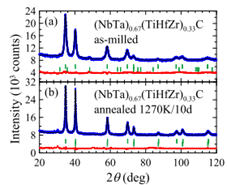

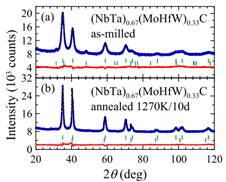

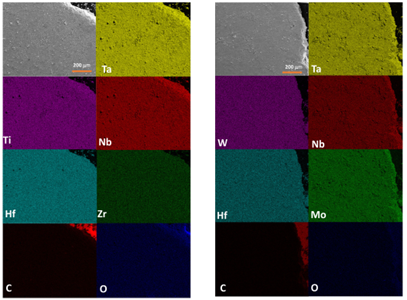

A group led by Professor Rafał Idczak from the University of Wrocław and Professor Adam Pikul from INTiBS PAN has developed a novel method for synthesizing high-entropy carbides. The method involves mechanical melting (grinding) of metal powder in a high-energy ball mill with toluene as a carbon source, and has allowed to produce high-quality (NbTa)0:67(TiHfZr)0:33C and (NbTa)0:67(MoHfW)0:33C. The process is carried out at room temperature, and does not require expensive metal carbides as substrates, making it cost-effective. This new method, developed by the team, is the first fully low-temperature method for obtaining carbides with high entropy.